In a world where materials must balance functionality, durability, and adaptability, PVC sheets have emerged as one of the most versatile and widely used solutions in both industrial and commercial environments. Known for their resistance to wear, ease of fabrication, and cost-effectiveness, PVC (polyvinyl chloride) sheets are now integral to an astonishing variety of applications, from healthcare and construction to signage and logistics.

Their increasing popularity is no accident. As industries become more complex and environmentally conscious, the demand for materials that can perform under pressure—literally and figuratively—continues to rise. PVC, with its highly customizable properties and long lifespan, is perfectly positioned to meet that challenge.

A Material That Adapts to Industry Demands

At its core, PVC is a thermoplastic polymer that becomes flexible or rigid depending on how it’s manufactured. This dual nature is what makes it so useful across sectors. Flexible PVC sheets can be found in applications like curtains, seals, and protective barriers, while rigid sheets are often used in wall cladding, roofing, and signage panels.

One of the key reasons PVC sheets are so widely adopted is their inherent chemical resistance and strength. Unlike many alternatives, they can withstand harsh industrial conditions without corroding or degrading, making them ideal for settings that require both sanitation and durability.

PVC Sheets in Construction

Perhaps one of the most prominent uses of PVC sheets is in the construction industry. Here, they’re used for wall cladding, insulation layers, floor protection, roofing, and even in temporary barriers or weatherproof sheeting. Their waterproof nature and resistance to impact make them especially effective in high-traffic or exposed areas.

PVC is also easy to cut, shape, and weld, which means it can be quickly adapted to suit a variety of projects—from major infrastructure developments to small-scale renovations. Furthermore, its low maintenance and easy-to-clean surface make it a long-term cost-saving material that is especially beneficial in commercial or industrial buildings.

Healthcare and Hygiene Applications

In sterile environments like hospitals, laboratories, and food processing facilities, cleanliness is paramount. PVC sheets play a critical role here due to their non-porous surface, which does not harbor bacteria and can be sanitized easily. In medical environments, they are often used as cladding for walls and ceilings, forming a barrier that complies with hygiene regulations while also being robust enough to withstand daily cleaning with strong disinfectants.

PVC’s adaptability also allows for the manufacture of antimicrobial sheets—products treated to inhibit bacterial growth—offering another layer of protection in sensitive settings.

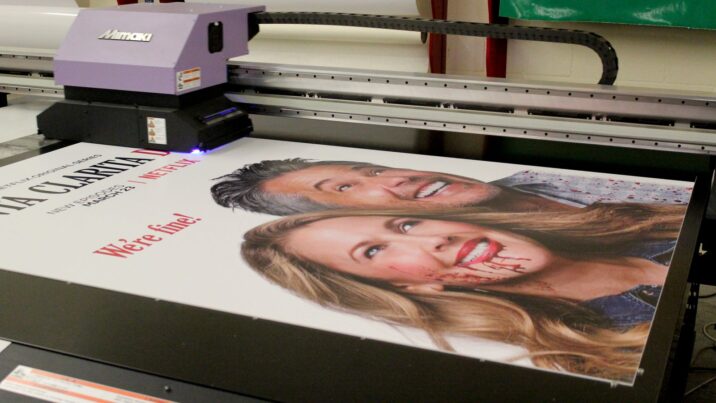

Signage and Display Uses

PVC is one of the most popular materials used in the advertising and signage industry. Lightweight, durable, and printable, PVC sheets can be used for indoor and outdoor signs, exhibition panels, retail displays, and directional signage. They maintain their structural integrity in different weather conditions and are easy to fabricate with various printing technologies.

Because they are available in various thicknesses, sizes, and finishes, they allow businesses to customize signage for branding while keeping production costs manageable. In addition, the clean, professional look of PVC panels provides an ideal surface for digital printing or vinyl application.

Warehousing, Logistics, and Manufacturing

In warehousing and logistics environments, PVC plays a vital role in partitioning spaces and improving operational efficiency. From strip curtains that help maintain temperature control to impact-resistant barriers that shield equipment and personnel, PVC sheets are an essential part of industrial safety and workflow design.

They are also commonly used to create conveyor belt covers, flexible partitions, machine guards, and dust barriers. Their strength, transparency (where needed), and ease of maintenance make them a go-to choice in environments where safety and visibility are critical.

Sustainability and Recycling

One of the growing concerns surrounding plastics is their environmental impact. Fortunately, PVC is one of the most recycled thermoplastics in the world. Modern recycling processes allow used PVC sheets to be ground down and remanufactured into new products, reducing waste and supporting a more circular economy.

Additionally, because of its durability, PVC has a significantly longer lifespan than many alternative materials. Its resistance to chemical damage, UV degradation, and physical wear ensures fewer replacements are needed, contributing to both sustainability and cost-efficiency.

Customization for Specific Needs

No two industries have identical needs, and that’s where the versatility of PVC sheets truly shines. Manufacturers like Rayflex Rubber provide high-specification sheet materials tailored to exacting requirements, whether for thermal resistance, impact tolerance, or hygiene compliance.

This level of customization allows businesses to choose sheet thickness, color, finish, and other variables to match their specific environments. For example, transparent PVC panels may be used in cleanrooms, while colored sheets help in coding and organization within warehouses or laboratories.

Easy Installation and Cost Benefits

PVC sheets offer relatively low installation costs and fast deployment compared to other industrial materials. Their lightweight nature makes them easy to transport and handle, while their compatibility with adhesives, mechanical fixings, and welding techniques ensures flexibility in installation.

For businesses, this translates into less downtime and reduced labor costs—two critical considerations in fast-paced industrial sectors. The material’s minimal maintenance requirements and excellent lifespan, even under challenging conditions, further bolster long-term savings.

The Future of PVC in Industry

As industrial requirements evolve, the demand for adaptable, cost-effective, and environmentally responsible materials will only increase. PVC sheets, already an indispensable component in dozens of industries, are likely to see expanded applications in areas like energy, technology, and sustainable construction.

Advancements in manufacturing are also leading to the creation of higher-grade PVC compounds with improved temperature tolerance, flexibility, and environmental resistance. These innovations will only enhance the value proposition of PVC for modern enterprises seeking smart material solutions.

PVC sheets** have firmly established themselves as one of the most practical and flexible materials for industrial and commercial applications. Whether used in construction, healthcare, signage, or warehousing, their blend of durability, hygiene, cost-effectiveness, and ease of customization makes them a material of choice for businesses across the globe.

With trusted suppliers like Rayflex Rubber delivering high-spec PVC and rubber products to meet diverse industrial needs, companies can confidently invest in materials that perform under pressure while supporting operational efficiency and sustainability goals.